Posted by: Marco Citossi

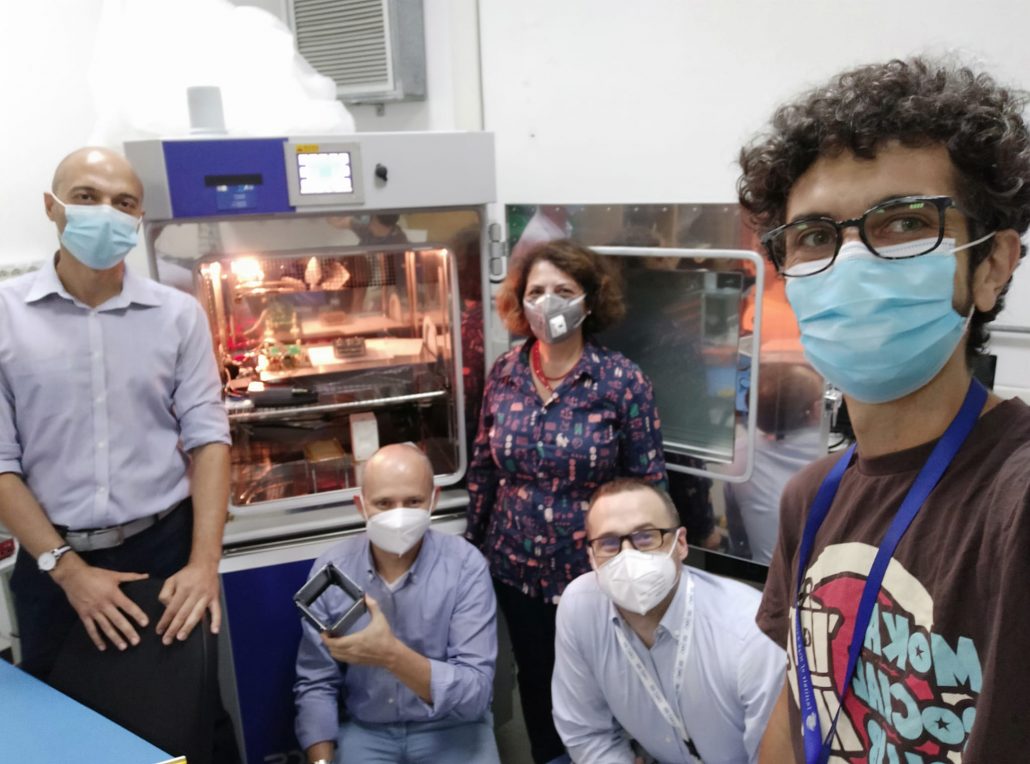

Integration of HERMES detector system at FBK Labs

The activities of integration and test of the hermes payload resumed at FBK labs starting from the beginning of June 2020 with the preparation of the jigs needed for the integration, and the finalization of the procedure for the SDD reinforcement.

Schedule (Jul. 27 – Sept. 11)

| 1 | Crystal Wrapping & crystal box assembly | 2020 June 30. @FBK + INAF team |

| 2 | ABS and Kovar frame manufactorig | 2020 July 7-13. @FBK |

| 3 | Glueing pf ABS and Kovar frame on SDD | 2020 July 14-22. @FBK |

| 4 | Probe station measurements of reinforced SDDs | 2020 July 16-24. @FBK + INFN Trieste |

| 5 | FEE PCB ASIC glueing | 2020 July 16-20. @FBK |

| 6 | FEE PCB reinforced SDD glueing | 2020 July 31 – Aug. 4. @FBK |

| 7 | FEE PCB bonding step 1 | 2020 Aug. 5-11. @FBK |

| 8 | FEE PCB ASICs electrical tests | 2020 Aug.10-13. @FBK + INAF/PoliMI team |

| 9 | FEE PCB bonding step 2 | 2020 Aug. 14. @FBK |

| 10 | FEE PCB complete electrical tests | 2020 Aug. 17-19. @FBK + INAF team |

| 11 | Crystal Box integration with FEE PCB | 2020 Aug 21. @FBK + INAF team |

| 12 | Functional test detector system | 2020 Aug. 24-26. @FBK + INAF team |

| 13 | Detector system transfer to Roma INAF/IAPS | 2020 Aug. 27 |

| 14 | Detector system characterisation | 2020 Aug. 28 – Sept. 3 @INAF/IAPS |

Crystal Wrapping & crystal box assembly

2020 June 30

FBK Labs + INAF team

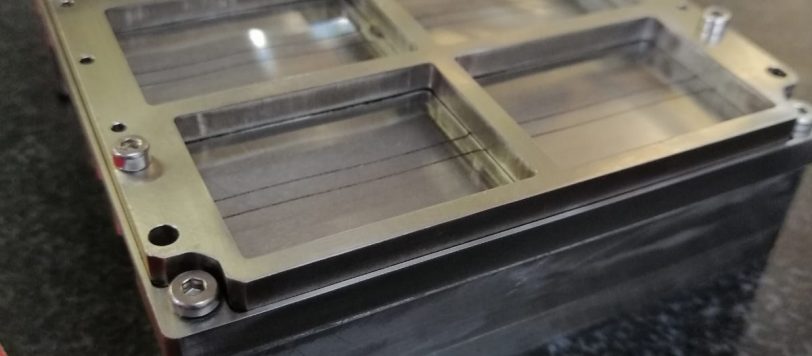

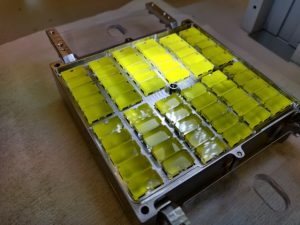

Before the integration of the scintillator crystals with the FEE-PCB, each crystal shall be individually wrapped with reflecting paper, and then assembled in 12 groups of 5 crystals each.

Insert one by one the 12 crystals groups into the rectangular slots.

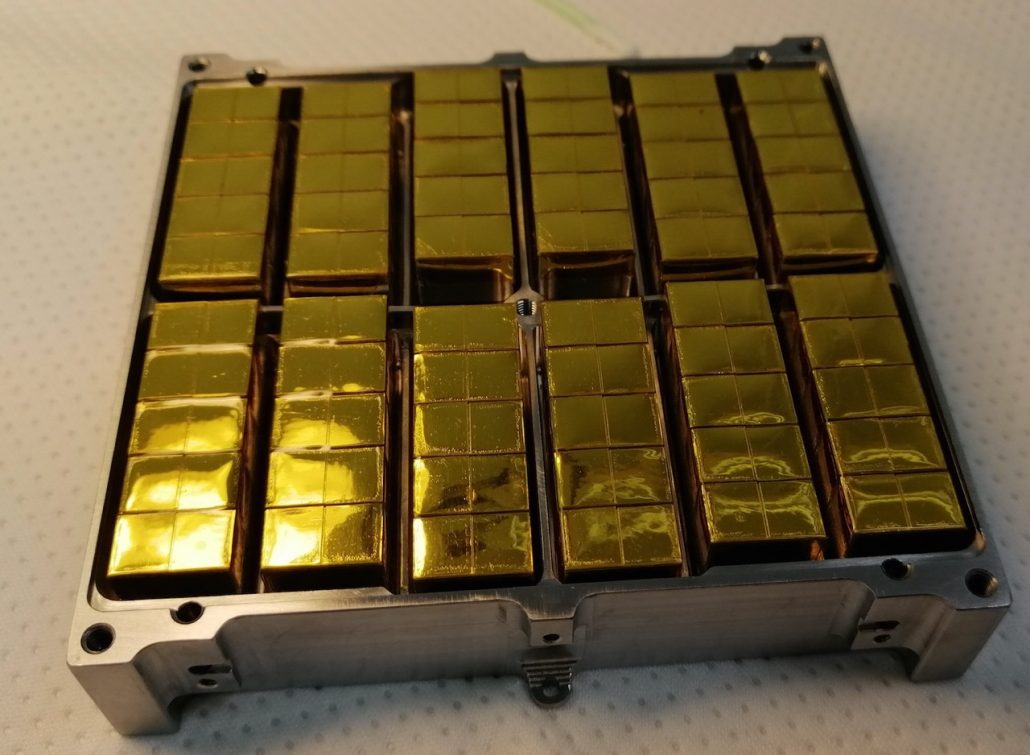

Figures show the crystal box populated with 60 wrapped GAGG crystals.

Crystal insertion in the crystal box

Crystal wrapping

ABS and Kovar frame manufactorig

2020 July 7-13

FBK Labs

SDD are fragile and before integration needs to be reinforced. The solution chosen after many mechanical and thermal tests performed in the months of February, May and June 2020 is to use ABS+Kovar frames.

Both FEM+thermal analyses and tests in thermal chamber validated this solution.

Frame manufacturing

SDD reinforced Frame is ABS reinforced with Kovar

glueing of frames on the SDD

Glueing of ASIC OnFEE board

FEE board on its jig ready for integration

LYRA-FE glued on the FEE PCB

LYRA-BE glued on the FEE PCB

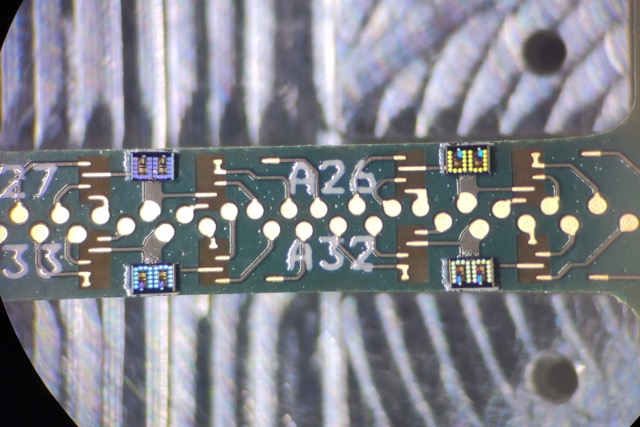

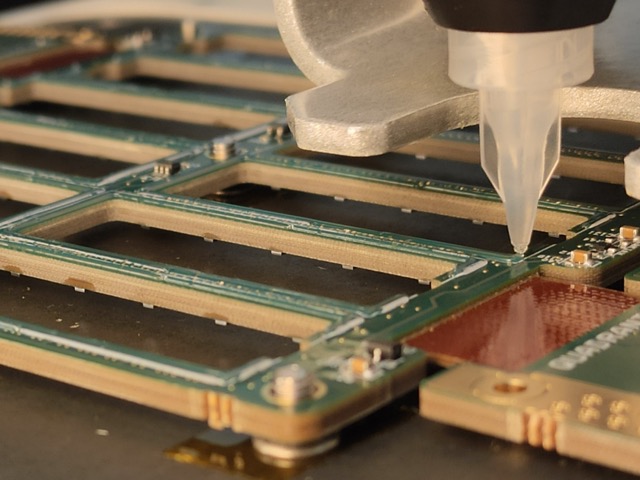

FEE PCB ASIC glueing

Depositing the glue on the FEE PCB

Particular of glue deposited on the FEE PCB

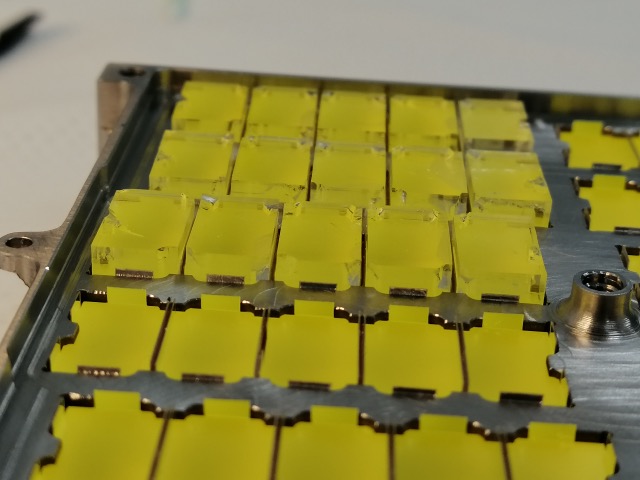

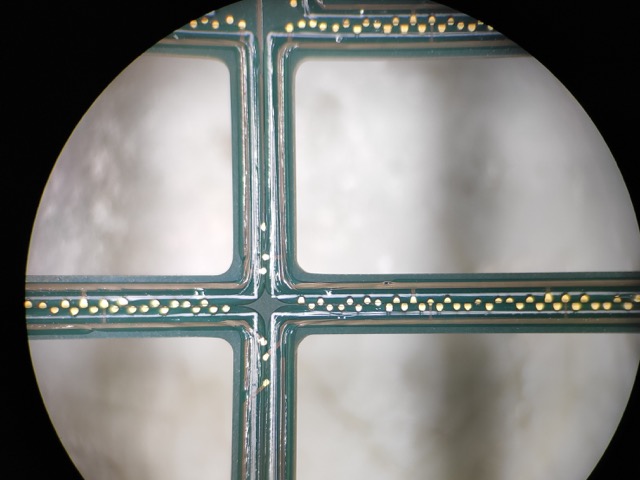

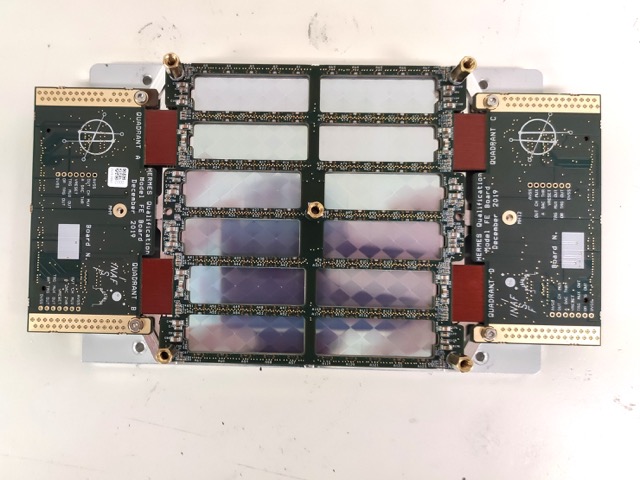

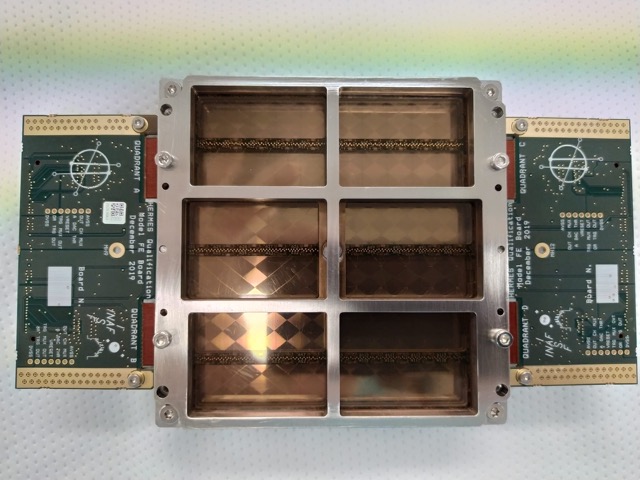

12 SDD mosaics glued on FEE PCB, still mounted in the jig. Planarity can be judged by the quality of the reflection

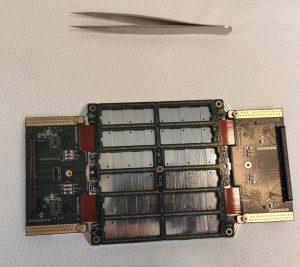

FEE PCB out of the jig after successful SDD glueing 2020 July 29

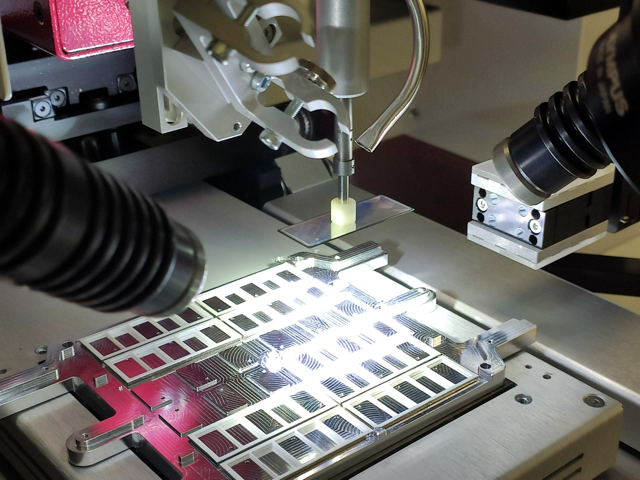

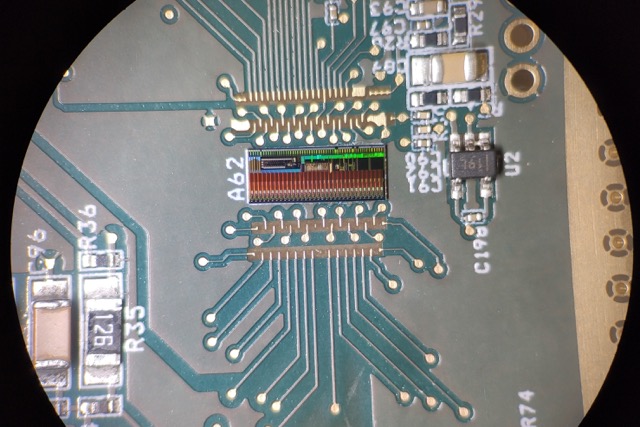

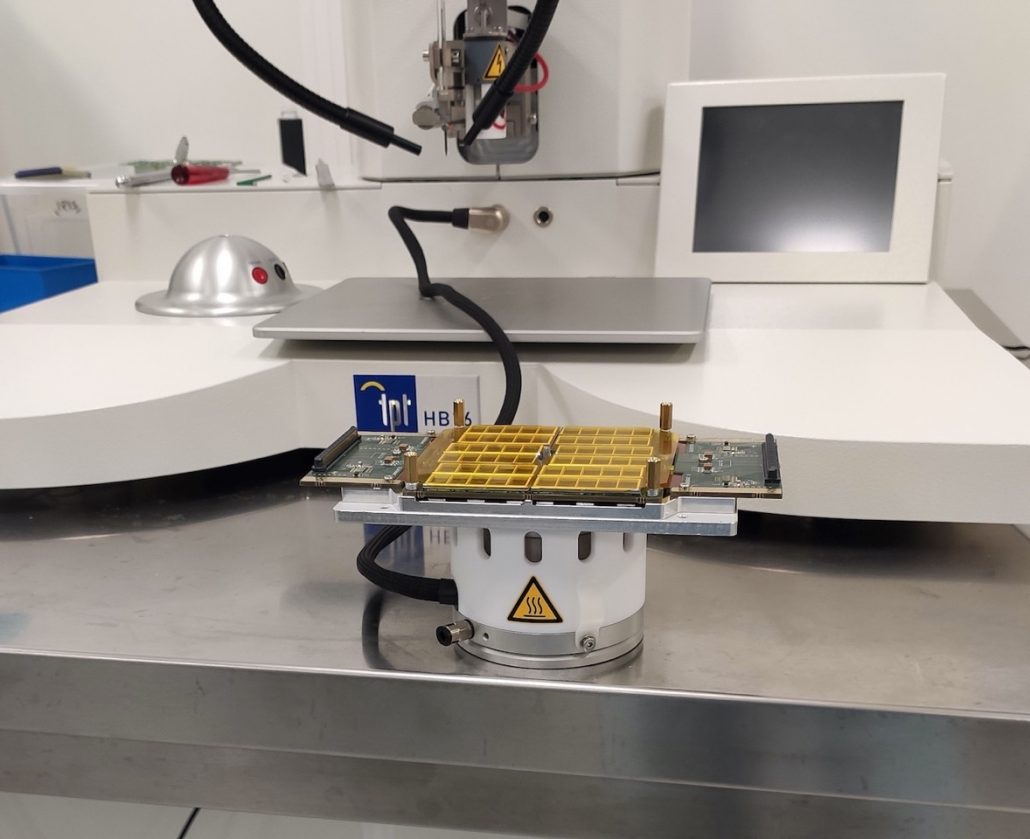

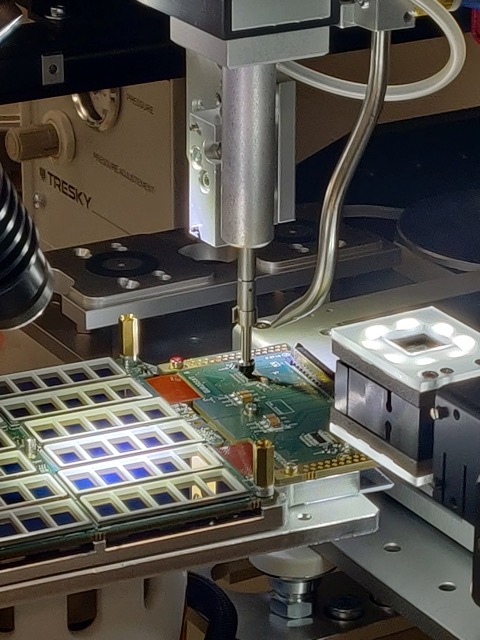

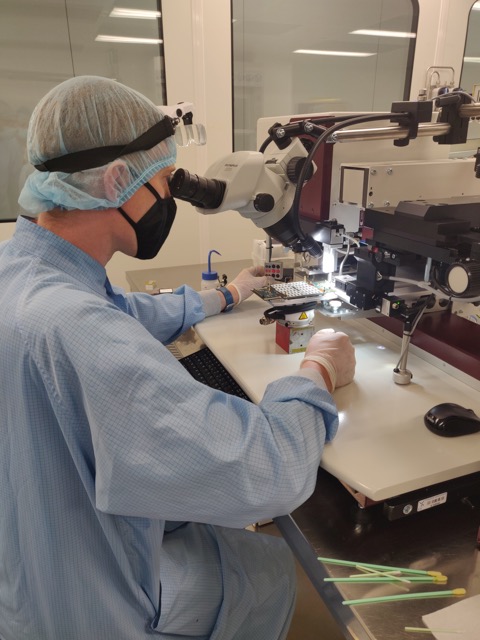

FEE PCB ready on the bonding machine

LYRA-BE pinout

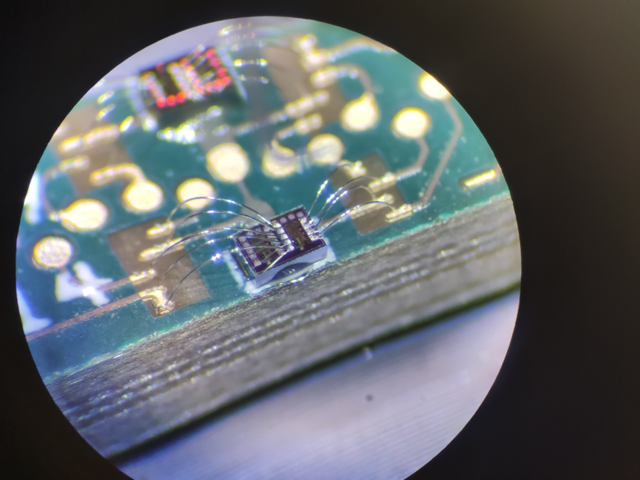

During LYRA-BE bonding

Bonding of LYRA-FE

Electrical test of all 120 LYRA-FE and 4 LYRA-BE effectuated (Aug. 10-13) before starting the operation of bonding of the SDD, which lasted until Aug 24-25).

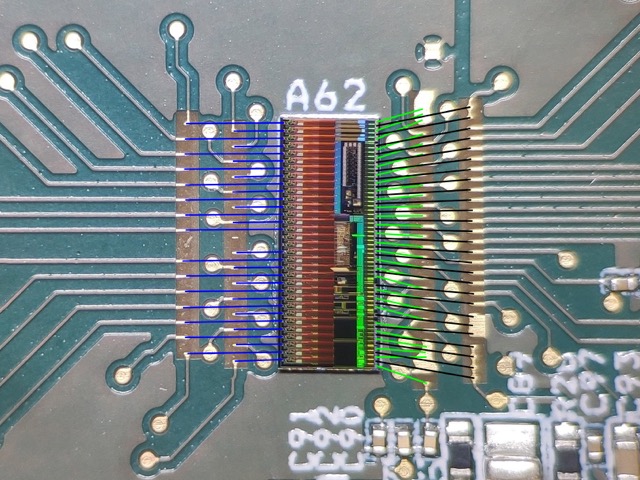

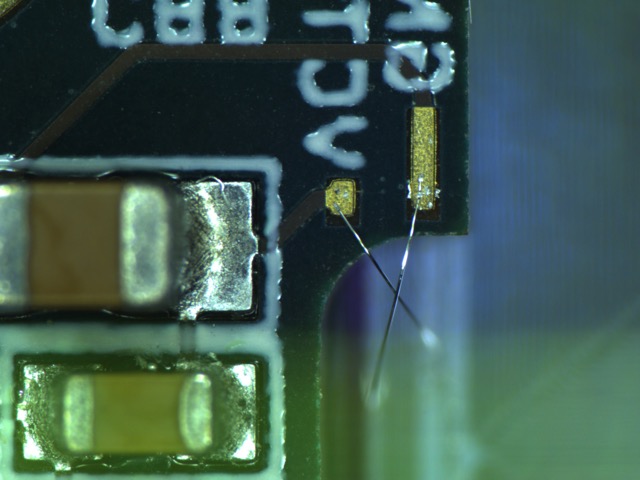

For each of the twelve 2×5 SDD mosaic the following bondings are needed:

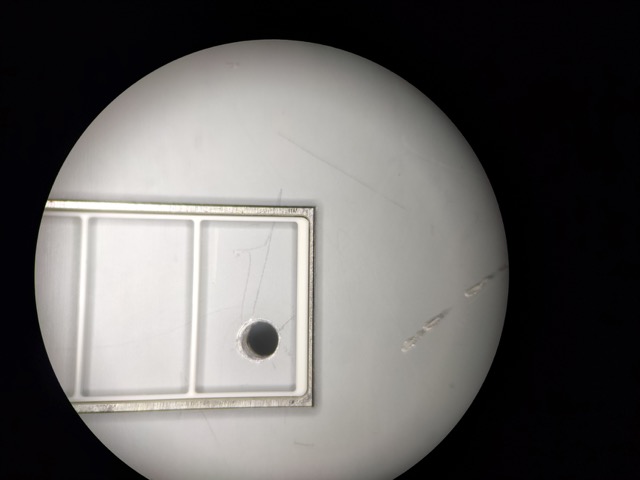

10 anod bondings (at the center of the SDD in the following figure) and 10 “return” bondings (the square left to the center in the figure), one for each SDD.

1 bonding for each mosaic for the VCTR and the Ground and 1 bonding for the UBIAS

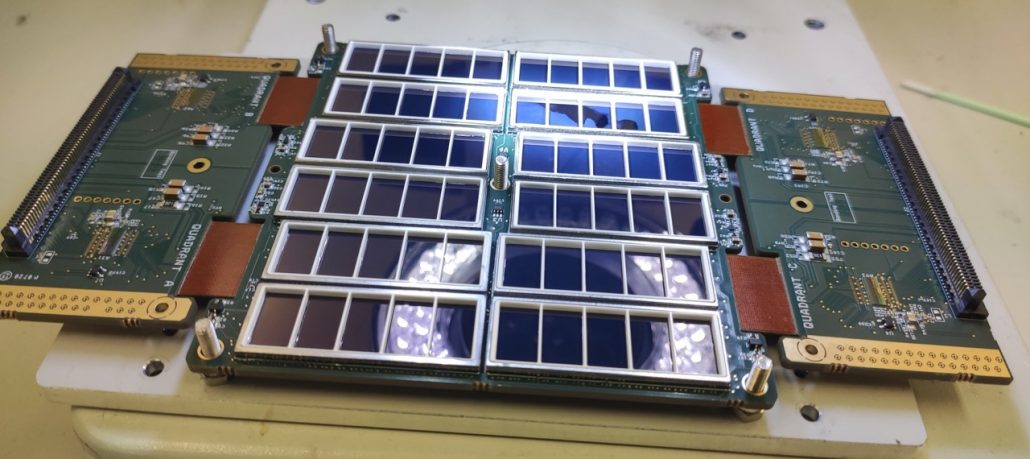

FEE PCB on the bonding machine during the procedure

After validation tests of the system after SDD bonding, the FBK and INAF teams proceeded to the integration of the FEE PCB with the crystal box.

The next figure shows the crystal box with silicone pads inserted. The silocone pads have the function to assure the optical coupling between the crystals and the SDDs.

The FEE-PCB has been then integrated with its support structure and with the crystal box.

Integrated detector system (Aug. 26)

Integrated detector system (Aug. 26)

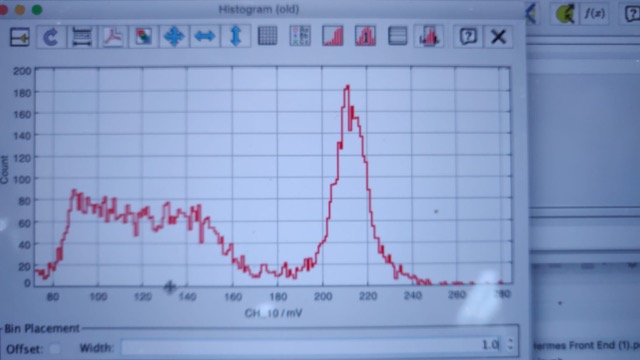

A first test of the integrated system has been executed at FBK labs with a Cesium radiactive source. The detector system is then connected with ground system equipment for a first test acquisition.

Cesium radiactive source (the black round element)

HERMES payload “first light”, the first Cesium137 spectrum (Aug. 27th)

The detector system has been then packed and transferred to INAF-IAPS laboratories in Roma, for functional tests and characterization (Aug. 28). The following figure shows the system in the climatic chamber at IAPS Roma ready for tests (Aug. 31st – Sept 11).